-

Feldspar is an aluminosilicate mineral of alkali metals or alkaline earth metals such as potassium, sodium and calcium, also known as feldspar group minerals.

Potassium feldspar (K2O·Al2O3·6SiO2), also known as orthoclase, belongs to the monoclinic crystal system, and is usually fleshy red, white, or gray. The potassium feldspar series are mainly orthoclase, microcline feldspar, and feldspar.

Potassium Feldspar

How to choose 300 mesh potassium feldspar grinding equipment?

The density of potassium feldspar is 2.56g/cubic centimeter, and the Mohs hardness is 6.

Considering the material characteristics and the requirements of 300mesh finished products, it is recommended to choose a Raymond mill. Except, what equipment is needed for the potassium feldspar grinding powder production line? It is also necessary to combine the particle size, output, and consideration of site conditions, floor space, investment budget, etc., here is a tailor-made solution for each customer.

As the main equipment, the Raymond mill is designed by updating and improving. It has a three-dimensional structure, small footprint, strong complete set, and an independent production system from block material to finished powder. The workshop can basically realize unmanned operation, High efficiency, coupled with new pulse dust removal equipment, complete dust removal and reduce pollution, the finished fine powder has good quality, uniformity, high sorting accuracy, and higher sieving rate, and the fineness can be adjusted arbitrarily according to needs.

Raymond mill for potassium feldspar

Production process of potassium feldspar powder

The first stage: The large pieces of potassium feldspar are transported by vehicles to the raw material warehouse, and then the materials are sent to the jaw crusher by forklifts/manually to be processed to the fineness (15mm-30mm) that can enter the mill.

The second stage: The crushed small pieces of potassium feldspar are sent to the silo by the bucket elevator, and then sent to the Raymond mill evenly and quantitatively by the vibrating feeder, and the grinding chamber is ground for grinding.

Three stages: The ground potassium feldspar powder is classified by the powder separator, and the unqualified powder is classified by the powder separator and then returned to the main engine for re-grinding.

Four stages: The powder that meets the fineness enters the dust collector through the pipeline with the airflow for separation and collection. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then the powder filling tanker or automatic baler is used uniformly to pack.

Frequently asked questions about potassium feldspar powder processing:

1. Does anyone know how the potassium feldspar ore powder is ground?

Q: Have you ever processed potassium feldspar ore? Does anyone know how it is processed into potassium feldspar powder

Answer: Potassium feldspar ore powder is processed by potassium feldspar mill, and can be applied to various industrial fields after processing. Use a suitable pulverizer (YGM type) with good fineness, which can grind 80-325 mesh.

2. Is the water after the production of the potassium feldspar powder factory toxic?

Answer: There must be pollution, mainly depends on whether you use other chemical materials.

3. What milling production line can be used to process 300 mesh potassium feldspar and albite?

Q: If I want to process 300 mesh feldspar powder, I don't know what mill to use? Can HGM series mills be processed? does anyone know

A: What you mentioned is possible. There are many production line equipment for potassium feldspar and sodium feldspar mill, including vertical mill, ultrafine mill and Raymond mill. It is more appropriate to choose a cost-effective production line equipment for the processing of 300-mesh potassium feldspar albite.

FAQ

Who we are?

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

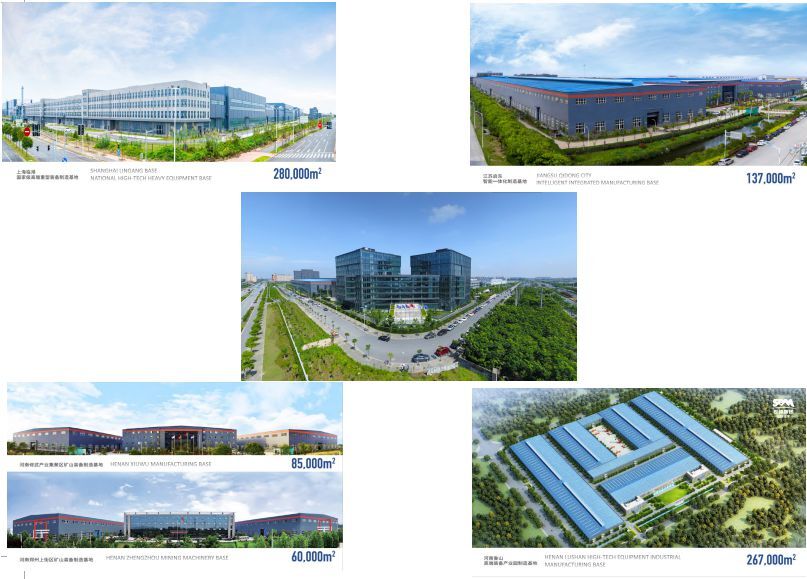

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Which models can be selected for processing ultra-fine powder?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: [email protected]

WhatsApp: +8613512155195/+8613917147829