-

Bentonite is an aqueous clay ore mainly composed of montmorillonite, with Moh's hardness of 1 ~ 2. It is a kind of soft non-metallic ore.

It has good expansibility, adsorption and pulping properties. After milling, it can become a binder, catalyst, decolorizer, etc. it is widely used in more than 100 departments, such as metallurgy, casting, chemical industry, food, building materials, petroleum, textile, ceramics, machinery, etc., with considerable industrial value.

What equipment is used to grind bentonite into powder?

Usually, the "crushing+grinding" combined processing process is used. The core equipment used includes Raymond mill or ultra-fine mill, and the auxiliary equipment includes jaw crusher, bucket elevator, electromagnetic feeder, etc. the author briefly introduces the series of equipment.

1. Raymond mill for bentonite

Raymond mill is also called Raymond mill. The CLIRIK mill adopts the advanced structure of similar products at home and abroad, and is updated and improved on the basis of Raymond mills in the same industry. This equipment is more efficient and consumes less electricity than ball mills. , Small footprint, small one-time investment. It is mainly suitable for the high-fine powder processing of non-flammable and explosive materials in mineral, chemical, construction and other industries with Mohs hardness not greater than 9.3 and humidity below 6%. The particle size of the finished product can be adjusted arbitrarily within the range of 80-325 mesh, and some materials can reach up to 600 mesh.

2. Micro powder mill for bentonite

Micro powder grinding mill is mainly suitable for the fine powder processing of non-flammable and explosive brittle materials with counterweight, low hardness and Mohs hardness ≤6. It is aimed at the needs of the development of the grinding industry and absorbs new grinding technologies and concepts at home and abroad. The new product with relatively advanced technology level has the advantages of greater grinding pressure, small investment, high profit, large feed size, fine output size, etc. It is an ideal equipment for bentonite grinding.

3. Ultrafine vertical grinding mill for bentonite

Ultrafine vertical grinding mill, also known as ultra-fine mill, consists of a main machine, a blower, an ultra-fineness analyzer, a finished cyclone powder collector, a bag filter and a connecting air pipe. It is mainly suitable for the grinding of various non-flammable and explosive mineral materials with a humidity below 6% on the Mohs level. The output fineness can reach 3250 meshes. Compared with other grinding equipment, the finished product has a finer particle size. It can be said that superfine grinding is a grinding machine with advanced technology, energy saving and high yield.

4. Three-ring medium-speed micro-powder mill for bentonite

Three-ring medium-speed micro-powder mill is also a common equipment for bentonite grinding. It is mainly suitable for processing ultra-fine powder of non-flammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤6. It has the performance advantages of high-yield, energy-saving, high product granularity, environmental protection and cleanness, and is an ideal equipment for green and environmental protection.

Auxiliary equipment for bentonite grinding

1. Jaw crusher

The equipment is used for simple initial crushing of bentonite. It has simple structure, high crushing efficiency, energy saving and consumption reduction, low carbon and high yield. The broken bentonite is of high quality, which promotes the simpler milling stage and high efficiency, and helps to improve the quality of finished products.

2. Bucket elevator

It mainly undertakes the transportation task of bentonite, and has the characteristics of low maintenance cost, high transportation efficiency and stable operation. Bucket Elevator

Bucket Elevator3. Electromagnetic feeder

The equipment can uniformly and effectively feed the broken bentonite into the host equipment. It has the advantages of small volume, high efficiency, more uniformity and long service life.FAQ

Who we are?

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

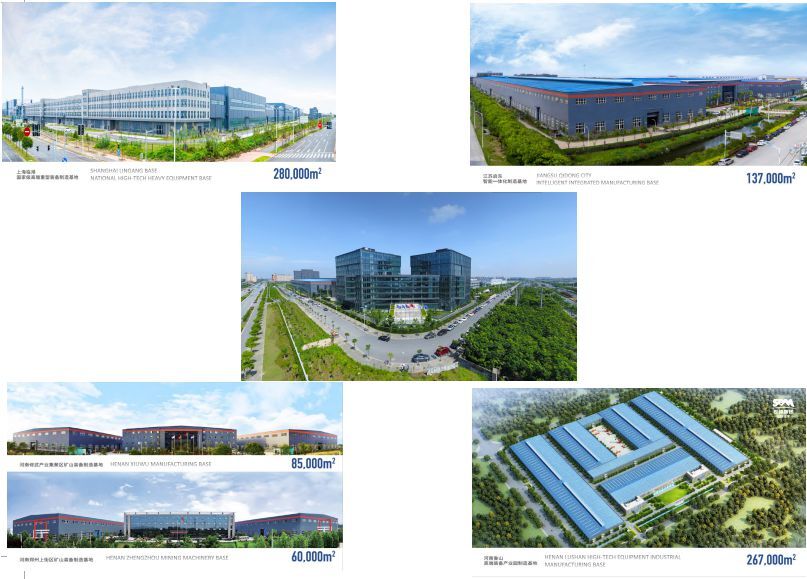

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Which models can be selected for processing ultra-fine powder?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: [email protected]

WhatsApp: +8613512155195/+8613917147829