-

Volcanic rock is a kind of vitreous lava with dense pores formed by the rapid cooling of magma in the process of volcanic eruption, due to the rapid reduction of pressure and the rapid overflow and expansion of internal gas. The hardness of volcanic rock is 5.08 MPa, which is a high hardness ore. When grinding, volcanic rock grinding equipment with strong compressive ability and good wear resistance should be selected.

Volcanic RockThe pore volume of volcanic rock accounts for more than 50% of the rock volume. It is called pumice because it has many pores, light weight and can float on the water surface. It is characterized by high strength, heat preservation, heat insulation, sound absorption, fire resistance, acid and alkali resistance, corrosion resistance, and no pollution, no radioactivity, etc.Volcanic rock is hard and difficult to process, so professional volcanic rock grinding equipment is required. CLIRIK manufactures various grinding equipment.The vertical grinding mill is specially designed for the production of wear-resistant pipes after crushing high-hardness materials.In addition to vertical mills, there are also ultra-fine mills, Raymond mills and other equipment. Ultrafine vertical mill is an ideal equipment for mass production of 325-2500 mesh volcanic rock, which can increase the added value of volcanic rock.

Volcanic RockThe pore volume of volcanic rock accounts for more than 50% of the rock volume. It is called pumice because it has many pores, light weight and can float on the water surface. It is characterized by high strength, heat preservation, heat insulation, sound absorption, fire resistance, acid and alkali resistance, corrosion resistance, and no pollution, no radioactivity, etc.Volcanic rock is hard and difficult to process, so professional volcanic rock grinding equipment is required. CLIRIK manufactures various grinding equipment.The vertical grinding mill is specially designed for the production of wear-resistant pipes after crushing high-hardness materials.In addition to vertical mills, there are also ultra-fine mills, Raymond mills and other equipment. Ultrafine vertical mill is an ideal equipment for mass production of 325-2500 mesh volcanic rock, which can increase the added value of volcanic rock.Volcanic rock vertical grinding mill

1. Raymond MillRaymond mill is a cost-effective equipment in volcanic rock grinding.2. Ultrafine grindingHow to choose volcanic rock grinding equipment?

Having said so much, many customers are still confused when choosing volcanic rock grinding equipment, and do not know what kind of equipment to choose and what type of equipment. As a professional pulverizer manufacturer, CLIRIK gives you the following suggestions: The two main indicators for the selection of volcanic rock pulverizers are: 1. The fineness of the output material, that is, the fineness of the final volcanic rock powder; 2. The hourly output requirement. After determining these two points, you can roughly determine the suitable model.Popular Questions and Answers about Mills

Q: What is the effect of the high current of the main motor of the coal mill?Answer: The current of the coal mill increases, the vibration value rises, and it will cause high wear on the grinding parts, and the grinding capacity will not increase accordingly.possible reason:a) The coal mill is overloaded or the coal is too wet;b) The pulverized coal is too fine;c) Motor failure;d) The gear box fails;e) ammeter failure;f) The primary air controller fails.solution:a) Reduce the coal feed rate, check the coal feeder calibration, coal hardness and coal temperature variation;b) Reduce the speed of the separator and adjust the opening of the folding door;c) Check the motor;d) Check whether the gears and bearings in the reduction box are faulty;f) Test and calibrate the current sensor;e) Shut down the coal mill, check and repair as required, check the temperature probe, differential pressure sensor and controller, calibrate and repair as required.Q: Is there a lot of dust during the operation of the pulverizer? Is it noisy?Answer: Hello, the mills produced by our company are basically equipped with dust-proof devices and silencers. The sealing method is very reasonable and effective, which basically avoids the emission of dust and noise.Q: What is the processing capacity of the vertical mill? How many tons per hour?Answer: Hello! There are 25 models of vertical pulverizers, each with different processing capacity, and the hourly output ranges from 4-320T/H.Q: Does your company have dolomite powder processing equipment above 325 mesh?Answer: Hello! The European version of the pulverizer can reach more than 325 meshes. The European version of the pulverizer is a new type of Raymond mill developed on the basis of the Raymond mill. The European version of the pulverizer is a product developed by our company on the basis of absorbing the pulverizing technology and concept. The grinding efficiency is high, and the output is increased by more than 20%.FAQ

Who we are?

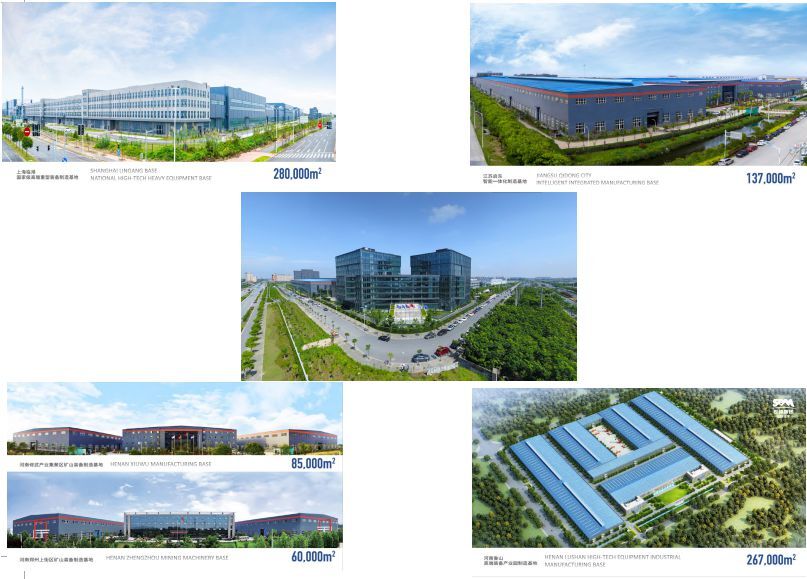

Shanghai CLIRIK Machinery Co.,Ltd. has been committed to the field of ultra-fine powder grinding machines for 20 years.

CLIRIK has a first-class manufacturing base with standardized and intelligent production lines.

CLIRIK's professional R&D, sales, installation and after-sales teams have provided door-to-door services to more than 100 countries and regions.

Which models can be selected for processing ultra-fine powder?

HGM grinding mill: 74-5 micron(200-2500 mesh); D97=5 micron

YGM Raymond mill: 613-33 micron(30-325 mesh); D90=30 micron

CLUM vertical roller mill: 20-5 micron(600-3000 mesh); D50=2 micron D97=4 micron

How to get the latest quotation?

You can leave a message online or contact CLIRIK directly:

Email: [email protected]

WhatsApp: +8613512155195/+8613917147829